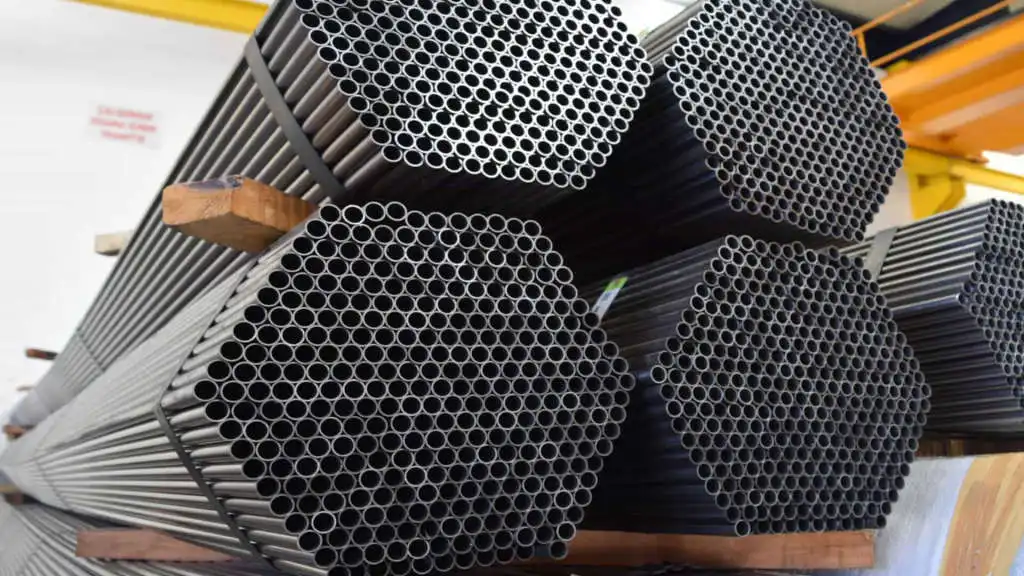

Annealed Black Flat End Pipe

Our Annealed Black Flat End Pipes; It is CE certified. Each of our pipes is subjected to leakage test under 50 bar pressure and eddy current (E/C) test. Annealing is a thermal procedure and it is a procedure applied at 1050 °C, which causes positive changes in the properties of the pipe such as strength, hardness and elasticity, and changes the material on a micro scale. Thus, simple welding and long life are ensured. The ovolite tolerance of our Annealed Black water pipes is narrow. When the pipes are brought end to end, they provide a perfect overlap along all axes. No weld runoff and no weld gaps that need to be filled in extra. A fast, comfortable and reliable pre-welding preparation is made. This simplifies butt welding.

Chemical and Mechanical Properties

|

Chemical Composition (%)(1)

|

|

|

|

Standard Equivalent

|

ERDEMIR

|

C max.

|

Mn max.

|

Si max.

|

P max.

|

S max.

|

Cu max.

|

|

Standard

|

Quality

|

Quality No.

|

|

EN 10217-1

|

P235TR1

|

3285(1)(2)(4)

|

0,16

|

1,2

|

0,35

|

0.025

|

0.020

|

0,3

|

|

EN 10217-1

|

P235TR1

|

3337 (3)(4)

|

0,16

|

1,2

|

0.040

|

0.025

|

0.020

|

0,12

|

Descriptions

Cr + Cu + Mo + Ni sum max. It should be 0.70%.

- It is Cu alloyed.

- It is a low silicon steel suitable for galvanized coating.

- These quality products are produced as fully stagnant, so Al/N is at a minimum 2:1 ratio.

Mechanical Properties (2)

|

|

|

Standard Equivalent

|

ERDEMİR

|

Re N/mm2 (kg/mm2)

|

Rm(1)

|

A5 (%) min.

|

|

Qualtiy No

|

1.50<d<16 min.

|

16<d<40 min.

|

N/mm2 (kg/mm2)

|

|

Standard

|

Quality

|

|

|

|

EN 10217-1

|

P235TR1

|

3285

|

235 (24.0)

|

225 (23.0)

|

360-500 (36.7-50.9)

|

23

|

|

EN 10217-1

|

P235TR1

|

3337(3)

|

235 (24.0)

|

225 (23.0)

|

360-500 (36.7-50.9)

|

23

|

Descriptions

- The tensile test values are applied to the ‘transverse’ test specimens.

- Mechanical values are guaranteed on hot rolled tape.

- It is produced up to a maximum thickness of 25 mm.