UPN Iron

What is UPN iron?

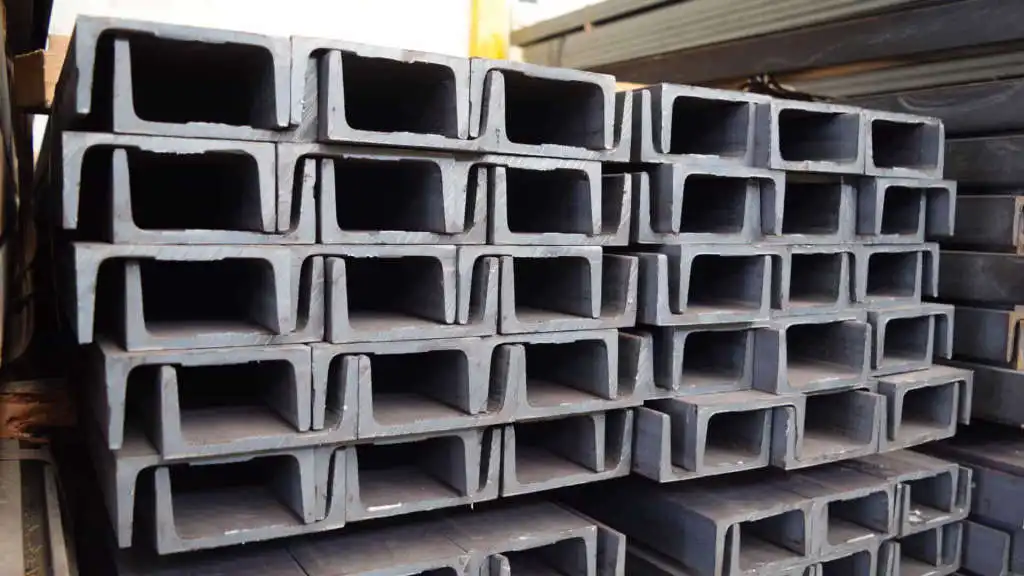

Among the products that emerged in parallel with the development of material science and offer higher performance compared to the past, UPN irons have a privileged place. UPN iron profiles, which are in the shape of a small n letter and have two vertical sides and a horizontal floor, reinforce the durability in the areas where they are used.

UPN iron profiles, which are shaped by passing through hot rolling processes, thus become more durable. In addition, UPN iron profiles, which have undergone a series of processes to increase their resistance to corrosion, have the qualities that can be used comfortably even in areas where the risk of corrosion is high. This means that UPN irons have a longer life and reduce costs in the long run.

Types of UPN iron

UPN iron types emerged in parallel with the increasing need after the benefits provided by these products. There is no clear difference between UPN iron types and normal UPN profile irons in terms of features. The main reason for the variation is that the area where the iron will be used is not reasonable to place the n-shaped material. For this reason, UPN profile irons are transformed into new types by changing their form. C profile irons are the first and most important models in this direction. C profile irons, which are the side-turned shape of classical n-shaped UPN irons, fulfill the same function in areas where n profiles are not reasonable. Another UPN iron type is U profile iron. These are also produced by turning the n profile iron completely upside down and are used for the same purpose.

European Standard Channel Beams

Dimensions:

DIN 1026-1: 2000, NF A 45-202: 1986

Tolerance Values:

EN 10279: 2000

Surface Condition:

Class C, subclass 1 in accordance with EN 10163-3: 2004 standard