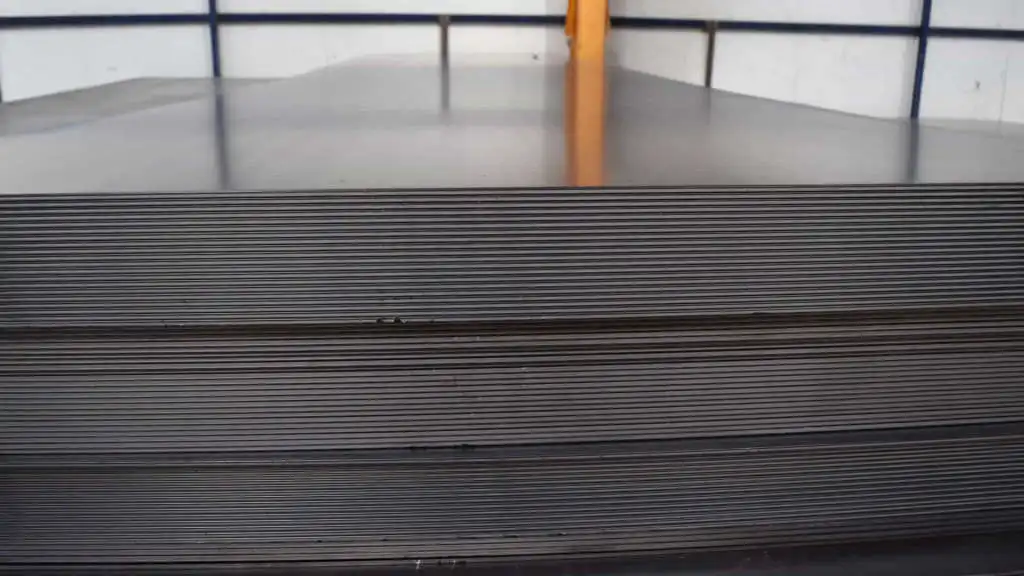

Acid Sheet - HRP

Scale (oxide) formed on Hot Rolled Roll surfaces is cleaned by passing through Hydrochloric acid or Sulfuric acid baths and lubricated with protective oil to prevent re-oxidation.

The product, which is called Acid Cleaned Sheet, is delivered to the user as a roll or as sliced and cut paint according to the demand.

(RP-RPD- RPKK- HRP – HRPKK-LP-LPKK-TRP-TRPD-TRPKK)

HRP Hot rolled, acid cleared, edges cut from coils HRPKK Hot rolled, acid cleaned, cut edges cut from coils 110

THRP Hot rolled, tempered, pickled, cut edge cut from coil

THRPK Hot rolled, tempered, pickled, uncut edge cut sheet from coil

HRP Sheet Properties

The characteristics of this material are the basis of the fact that HRP sheet products are becoming more and more common. HRP sheets, first of all, have a high strength value. Since they are subjected to both hot and cold rolling procedures, the resistance of HRP sheets increases to a great extent. However, the corrosion resistance of HRP sheets is also higher than that of normal iron. Even in areas where the risk of corrosion is high, it is possible to use this material for many years without any problems. HRP sheets also come to the fore with their welding retention levels. Welds applied to HRP sheets, which can bond strongly with other metals, can remain intact for a long time.

|

HR → HRP

|

Pickling Line

|

|

Material thickness

|

1.50 – 5.00 mm

|

|

width

|

600 – 1550 mm

|

|

Coil Inner Diameter

|

610 mm

|

|

Maximum Roll Weight

|

30 ton

|

Their quality

CONTINUOUS HOT ROLLED LOW CARBON STEEL FLAT PRODUCTS FOR COLD FORMING

|

No

(Nr)

|

Steel Quality

(Steel Ouality)

|

Steel Number

(Steel Number)

|

Product Form

|

Chemical Composition

(Chemica/ Compostion) ( % ) Max

|

Yield Strength

(Nlmm2)

|

Yield Strength

(Nlmm2)

|

Tensile Strength

(Nlmm2)

|

Elongation Amount (E/ongation) (

¾)Min

|

Elongation Amount(E/ongation) (

¾)Min

|

Elongation Amount

(Elongation) ( % ) Min

|

|

|

|

|

C

|

s;

|

Mn

|

p

|

s

|

1,00<e<2,00

mm

|

2,00<e<11,00

mm

|

RmMax.

|

1,00<e<1,50m

m

|

1,50<e<2,00m

m

|

2,00<e-<3,00mm

|

|

1

|

DD11

|

1.0332

|

HAP*

|

0.12

|

–

|

0.60

|

0.045

|

0.045

|

170-360

|

170-340

|

440

|

22

|

23

|

28

|

|

2

|

DD12

|

1.0398

|

HAP*

|

0.10

|

–

|

0.45

|

0.035

|

0.035

|

170-340

|

170-320

|

420

|

24

|

25

|

30

|

|

3

|

0013

|

1.0335

|

HAP*

|

0.08

|

–

|

0.40

|

0.030

|

0.030

|

170-330

|

170-310

|

400

|

27

|

28

|

33

|

|

4

|

DD14

|

1.0398

|

HAP*

|

0.08

|

–

|

0.35

|

0.025

|

0.025

|

170-310

|

170-290

|

380

|

30

|

31

|

36

|

(*)Hot rolled pickled material

HOT ROLLED, HIGH STRENGTH STEEL FLAT PRODUCTS FOR COLD FORMING

|

No

(Nr)

|

ÇSteel Quality

(Steeı Ouality)

|

Steel Number

(Steel Number)

|

Product Form (Form of Product)

|

Chemical Composition

(Chemical Compostion) ( % ) Max

|

Yield Stress (Yield Strength)

(Nlmm2)

(Min)

|

Shear Stress (Tensile Strength)

(Nlmm2)

|

Elongation Amount (Elongation) (

%,)Min

|

Elongation Amount (Elongation) (

¾)Min

|

|

C

|

s;

|

Mn

|

p

|

s

|

Al(min)

|

|

|

|

1

|

S315MC

|

1.0972

|

HAP *

|

0.12

|

0.50

|

1.30

|

0.025

|

0.020

|

0.015

|

315

|

390-510

|

20

|

24

|

|

2

|

S355MC

|

1.0976

|

HAP *

|

0.12

|

0.50

|

1.50

|

0.025

|

0.020

|

0.015

|

355

|

430-550

|

19

|

23

|

|

3

|

S420MC

|

1.0980

|

HAP *

|

0.12

|

0.50

|

1.60

|

0.025

|

0.015

|

0.015

|

420

|

480-620

|

16

|

19

|

|

4

|

S550MC

|

1.0986

|

HAP *

|

0.12

|

0.50

|

1.80

|

0.025

|

0.015

|

0.015

|

550

|

600-760

|

12

|

14

|

(*)Hot rolled pickled material

|

HOT ROLLED CONSTRUCTION STEELS Hot-rolled products for structural steels (HRP-TS EN 10025-2)

|

|

No (Nr)

|

Steel Quality (Steel Quality)

|

Steel Number (Steel Number)

|

Product Form(Form of Product)

|

Chemical Composition(Chemical Compostion) (%) Max

|

Yield Stress (Yield Strength) (N/mm2 ) (Min)

|

Shear Stress (Tensile Strength) (N/mm2 )

|

Elongation Amount (Elongation) ( %) Min

|

Elongation Amount (Elongation) ( %) Min

|

Elongation Amount (Elongation) (% ) Min

|

Elongation Amount (Elongation) ( %) Min

|

Elongation Amount (Elongation) ( %) Min

|

|

C

|

Mn

|

P

|

s

|

N

|

Cu

|

Rm Max.

|

e<1,00mm

|

1,00<e<1,50m m

|

1,50<e<2,00mm

|

2,00<e<2,50m m

|

2,50<e<3,00 mm

|

|

1

|

S235JR

|

1.0037

|

HRP*

|

0.20

|

1.40

|

0.04

|

0.040

|

0.012

|

0.550

|

235

|

360-510

|

17

|

18

|

19

|

20

|

21

|

|

2

|

S275JR

|

1.0044

|

HRP*

|

0.22

|

1.50

|

0.04

|

0.040

|

0.012

|

0.550

|

275

|

430-580

|

15

|

16

|

17

|

18

|

19

|

|

3

|

S355JR

|

1.0045

|

HRP*

|

0.24

|

1.60

|

0.04

|

0.040

|

0.012

|

0.550

|

355

|

510-680

|

14

|

15

|

16

|

17

|

18

|

Low Carbon Hot Rolled Steels Suitable for Cold Forming Chemical Composition (%)

|

Standard Equivalent

|

ERDEMİR

Kalite No

|

Deoxidation Method

|

C max.

|

Mn max.

|

P max.

|

S max.

|

Ti min.

|

|

Standart

|

Kalite

|

|

EN 10111

|

DD11

|

3222

|

–

|

0.12

|

0.60

|

0.045

|

0.045

|

–

|

|

EN 10111

|

DD11

|

4222

|

–

|

0.12

|

0.60

|

0.045

|

0.045

|

–

|

|

EN 10111

|

DD11

|

6222

|

–

|

0.11

|

0.5

|

0.035

|

0.035

|

–

|

|

EN 10111

|

DD11

|

6282(1)

|

–

|

0.12

|

0.60

|

0.045

|

0.045

|

–

|

|

EN 10111

|

DD12

|

6223(3)

|

fully stagnant steel

|

0.09

|

0.4

|

0.03

|

0.030

|

–

|

|

EN 10111

|

DD13

|

6224(2)3)

|

fully stagnant steel

|

0.07

|

0.35

|

0.025

|

0.025

|

–

|

|

EN 10111

|

DD11

|

7222

|

–

|

0.12

|

0.60

|

0.045

|

0.045

|

–

|

|

EN 10111

|

DD14

|

7224(3)

|

Tam durgun çelik

|

0.08

|

0.35

|

0.025

|

0.025

|

0.01

|

Mechanical Properties

|

Standard Equivalent

|

ERDEMİR

Quality No

|

Re N/mm2 ( kg/mm2 )

|

Rm(1)

N/mm2 ( kg/mm2 )

|

A (%)

|

Guarantee13) Time

|

|

A80

|

A5

|

|

Standard

|

Quality

|

|

1.5 < d < 2

|

2 < d < 11

|

max.

|

1.5 < d < 2 min.

|

2 < d < 3 min.

|

3 < d < 11 min.

|

|

EN 10111

|

DD11

|

(2)

3222

|

170 – 360 (17.3-36.7)

|

170 – 340 (17.3-34.7)

|

440

( 44.9 )

|

23

|

24

|

28

|

–

|

|

EN 10111

|

DD11

|

(2)

4222

|

170 – 360 (17.3-36.7)

|

170 – 340 (17.3-34.7)

|

440

(44.9)

|

23

|

24

|

28

|

–

|

|

EN 10111

|

DD11

|

(2)

6222

|

170 – 360 (17.3-36.7)

|

170 – 340 (17.3-34.7)

|

440

(44.9)

|

23

|

24

|

28

|

–

|

|

EN 10111

|

DD11

|

(2)

6282

|

170 – 360 (17.3-36.7)

|

170 – 340 (17.3-34.7)

|

440

(44.9)

|

23

|

24

|

28

|

–

|

|

EN 10111

|

DD11

|

(2)

7222

|

170 – 360 (17.3-36.7)

|

170 – 340 (17.3-34.7)

|

440

(44.9)

|

23

|

24

|

28

|

–

|

|

EN 10111

|

DD12

|

6223

|

170 – 340 (17.3-34.7)

|

170 – 320 (17.3-32.6)

|

420

(42.8)

|

25

|

26

|

30

|

6 ay

|

|

EN 10111

|

DD13

|

6224

|

170 – 330 (17.3-33.7)

|

170 – 310 (17.3-31.6)

|

400

(40.8)

|

28

|

29

|

33

|

6 ay

|

|

EN 10111

|

DD14

|

7224

|

170 – 310 (17.3-31.6)

|

170 – 290 (17.3-29.6)

|

380

(38.8)

|

31

|

32

|

36

|

6 ay

|

Usage areas

Surface smoothness, thickness, width and physical properties of these produced materials are produced according to expectations. In general, the area where they are applied is suitable for cold forming. Accordingly, kitchen utensils, ventilation, durable household appliances, automotive sector and radiator. It can be used in applications that users want.

It is used in the white goods industry, automotive industry, superior formability, resistance to aging and in areas suitable for extra deep drawing processes.

It is used during the manufacture of steels and kitchen utensils that have deep drawing properties and are suitable for enamel coating. (For example, items such as pots, oven grates, etc.) It may not always be appropriate to use due to scale on the surface of hot rolled sheets. Hot rolled degreased and pickled grades are generally used for deep drawing, bending and drawing processes.

These products do not have sensitive surface quality expectations. However, it can be used in all applications where rigidity, strength and plasterability are required. Sheets whose surface is cleaned with acid are used in the manufacturing sector of machines as well as in automotive sub-seconds. Cleaning the surface of the sheets with acid provides more economic benefits after machine manufacturing. For this reason, manufacturers generally prefer materials whose surface is cleaned with acid.

High strength steels suitable for cold forming can be preferred in all applications requiring high impact, formability and fatigue strength. It is used successfully during the manufacture of LPG cylinders. These products, which are used successfully in the building sector, are preferred because they can be shaped in general.