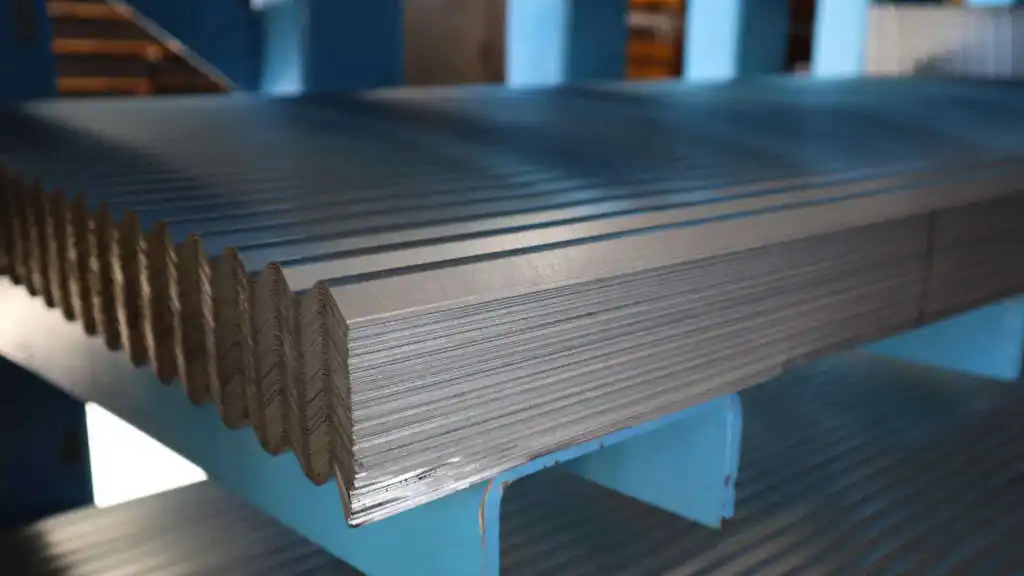

Roller Sheet

What is Roller Sheet?

It is the form of aluminum or painted products as roller blinds. Roller blinds can be drawn in any aluminum sheet size you want.

- If the blind is pulled out of 1000 mm wide material, the useful area will be 800 mm.

- If the roller is pulled out of 1250 mm wide material, the useful area will be 950 mm.

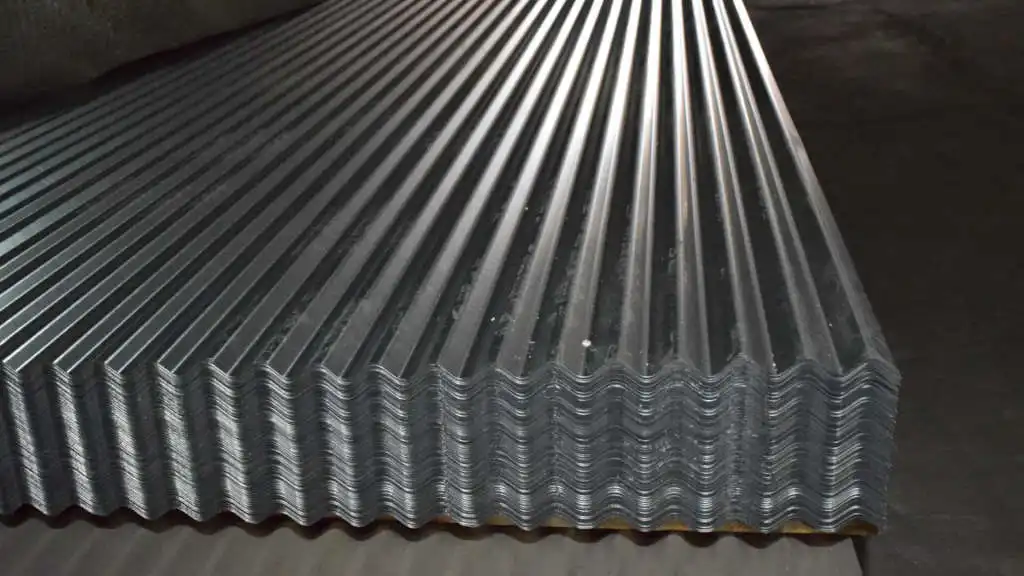

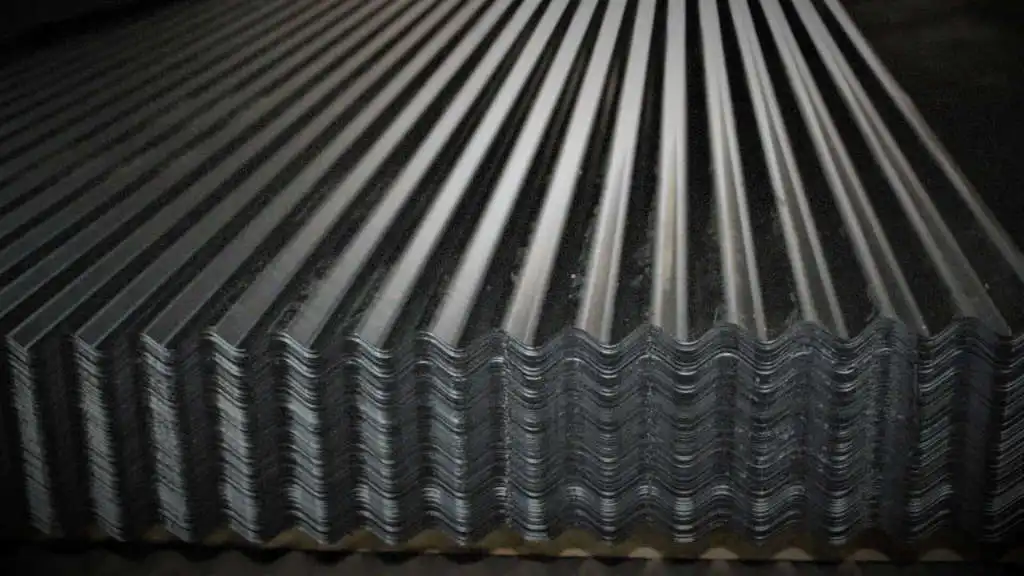

- Radius spacing is 3 cm (distance between two grooves width), Radius height can be adjusted between 10-20 mm.

- Sheet Thickness: Min. 0.30mm / Max. 0.70mm

- Sheet Length: Min. 1000mm / Max. 3200mm

- Sheet Useful Area Width: 804 mm (Tolerance: + 25 mm, -15 mm)