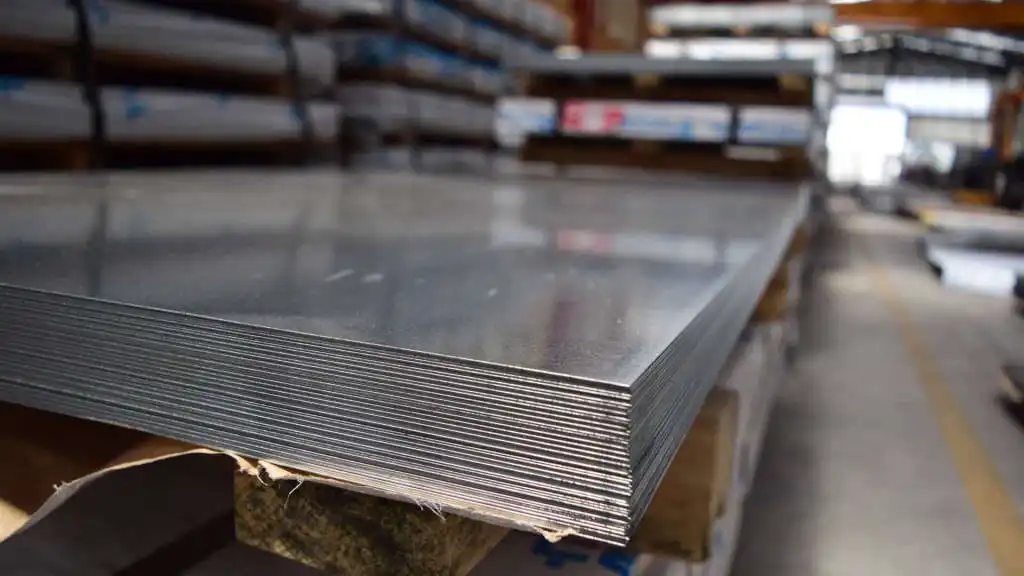

DKP Sheet

What is DKP Sheet?

DKP sheets can be obtained by passing thick plates between rollers, that is, by rolling. According to the demand, it is produced in a form that has either a roll or a flat appearance, and we can say that it is an extremely common use.

The thickness of DKP Sheets varies between 0.30 millimeters and 2 millimeters. This change determines the thickness of the products and the length and number of the rolling system.

DKP sheet is divided into many groups within itself. The usage area, feature and form of each variety differs.

This type of sheet can be obtained in different sizes during production. For example, it may be possible to produce between 0.2 mm and 2 mm according to the desired thickness. Between these two thickness units, there are many options depending on the area of use and need. At the same time, it can be produced as flat sheet or rolled sheet in line with the customer’s demand and needs.

Among the DKP sheet features, it may be possible to sell various types of kg according to customer demand. In this regard, there are kg sales options such as 1000 * 2000, 1200 * 2400, 1250 * 2500, 1500 * 3000. It may be possible to produce according to the need and usage area within all these thickness, shaping and kg properties.

These sheets, which have extremely high forming possibilities, provide simplicity of use in most areas. Therefore, the preference rate is extremely high.

– Deep drawing feature of DKP Sheets is one of the reasons why they are preferred in production and manufacturing that require toughness and flexibility.

– DKP coil sheet and DKP sheet plates are among the most preferred ones in the white goods industry, due to their simple forming and welding properties.

– DKP sheet is used more in kitchen utensils than enamel coating.

DKP Sacın Avantajları

Sheet metal usage areas have an extremely wide coverage. Where it is used, it gives a more aesthetic appearance than standard black steel. Thanks to this appearance, it can be used both indoors and outdoors.

The most important reasons that can be counted among the advantages of DKP sheet are as follows;

These sheets are extremely easy to form both during the production phase and during the usage phase. For this reason, it is preferred more than other sheets.

In terms of appearance, it has a brighter structure compared to classical sheet metals. Thanks to its smooth structure, it is more appealing to the eye in the area where it is used. It also provides simplicity in processes such as paint to be applied on it.

DKP sheet metal, which can be produced in the form of flat sheet or pipe sheet during the production phase, provides diversity regarding the field of use. The ability to format according to the required area also makes this product a reason for preference.

Another advantage is that it has many options in terms of thickness. With thickness options ranging from 0.2 mm to 2 mm, we produce sheet metal in the ideal size and thickness for your needs.

DKP sheet is a cleaner material than standard mild steel sheet. When two products are placed side by side, DKP sheet is clearly visible. In addition to all these features, it is not a stainless sheet. Despite this, it has a more durable structure compared to other sheets. If it is to be used outdoors, it can be made to last longer by painting.