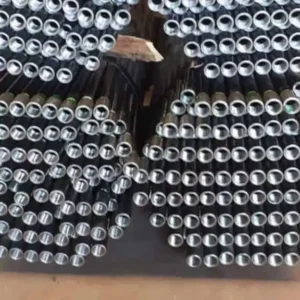

Galvanized Construction Pipes

Construction pipes are used in machinery parts or equipment manufacturing as well as superstructure constructions. Due to the fact that the steel drawing production technique is suitable for the supply of pipes with high wall thicknesses, it is used instead of solid (billet) materials during the manufacture of most machine parts, and it is also preferred in carrier columns that require high wall thickness as it will be under heavy load.

Production Standards

|

PRODUCTION STANDARDS

|

MATERIAL QUALITY

|

|

EN 10219-1/2 – CE DOCUMENTED

|

S235JRH, S235J0H, S235J2H

|

|

S275JRH, S275J0H, S275J2H

|

|

S355JRH, S355J0H, S355J2H, S355K2H

|

|

ASTM A-500

|

Gr A, Gr B, Gr C

|

|

EN 10305-5

|

E195, E235, E275, E355, E190, E220, E260, E320, E370, E420

|

The TS EN 10219 standard consists of 2 parts;

It includes TS EN 10219 Part 1: Technical Delivery Conditions and is named as TS EN 10219-1.

TS EN 10219 Part 2: Includes Tolerances, Dimensions and Section Properties and is named as TS EN 10219-2

The wrong point about the TS EN 10219 standard; that this standard is two separate standards, TS EN 10219-1 and TS EN 10219-2. This information is not correct, the TS EN 10219 standard consists of 2 separate parts mentioned above.

Usage areas

- Airport

- Bridges and Tunnels

- Factory Buildings

- Shopping malls

- Stadiums

- Many other carrier systems

Galvanized Construction Pipes are pipes whose surface is coated with zinc with a technique called hot dipping to protect the steel against many abrasions such as corrosion and humid environments. In addition, galvanized pipes provide high protection and economical solution against dangerous situations such as rain acid.

Galvanized Construction Pipes are mostly used in situations where metal needs to be protected against corrosion such as marine programs, constructions, interior installations, water lines, electricity/flag poles.