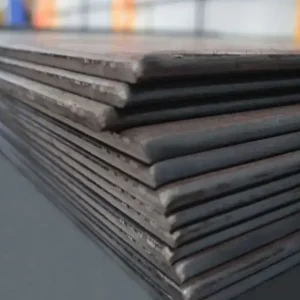

Galvanized Sheet DX 51-1311

What is Galvanized Sheet DX 51-1311?

Galvanized sheet is obtained by zinc coating of CR, and tin is obtained by tin coating. After the CR is produced or the galvanizing procedure is carried out, the sheet must be cut upon request.

Features of Galvanized Sheets Long Life, Zinc coating does not spill when folded, is suitable for deep drawing and plastering, holds solder easily, can be painted very simply, is fire resistant, economical, easy and resistant to many external factors.

What are the Features of Galvanized Sheet?

Moisture and soil are among the most damaging factors for iron and iron products. Iron and iron products exposed to moisture and wetness shorten the lifespan and lose their properties and resistance within a few years. This causes iron and iron products to lose their functions. For this reason, it increases the resistance of the products by means of galvanized sheet clothed on the sheet, and ensures that they are long-lasting in fulfilling their function. There are many features among the reasons why galvanized sheet is so preferred. Galvanized sheet establishes a barrier to the corrosive elements of the metal in its nature due to its corrosion resistance. Its easy formatting feature also causes it to expand its usage areas immensely. The feature makes it an optimal material for the production of parts requiring extra deep drawability and bending. It is frequently used because of its perfect surface appearance.

Weldability is among the galvanized sheet method features, they can be welded with most welding processes. Although it is paintable, galvanized sheet products can be painted simply if the preliminary procedures are done correctly. The preliminary procedures mentioned here are called degreasing procedures.