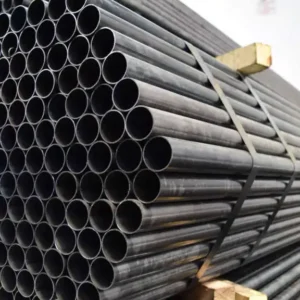

Industry Pipe

What is Industrial Pipe?

Industrial pipes are produced using high frequency welding (ERW) from hot rolled (HR) black or cold rolled (CR or DKP) raw material bands, in advanced technology machines according to TS EN 10305-5 and TS EN 10305-3 production standards.

Dimensions and Dimensions

In general, industrial pipe has standard types and dimensions. The industrial pipe has a size ranging from 13 mm to 219 mm in outer diameter. The part called wall thickness may vary according to the demand of the customer and the need of the area to be used. However, it generally differed between 0.50 mm and 8.00 mm sizes.

The standard industrial pipe lengths are 6 meters. However, it is also offered to you in sizes between 3.4 meters and 12.8 meters, depending on the need for reasonable use.

Usage areas

Industrial pipes, which find use in more than one sector, are especially used in construction and new constructions. It also finds use in areas such as ship transportation, road transportation, chemical transportation. The type and internal structure of the industrial pipe vary according to each type and structure of the liquid that will pass through or remain.

Industrial pipes are frequently preferred and used in the following areas;

- Different industrial facilities,

- Automotive industry,

- furniture industry,

- home appliance industry,

- It is used as a carrier building material in areas and units such as textile material production facilities and textile production centers.

Types

Industrial pipes have 3 different alternatives; Industrial pipe with protective oil, galvanized coated industrial pipe and painted industrial pipe. The galvanizing procedure is applied to hot rolled products, and the resulting product offers a long-lasting, highly corrosion-resistant alternative.

Industrial pipe obtained with water-based paint is also among the preferred alternatives. Red, gray and black color alternatives are supplied according to the customer’s choice.

Pipes coated with protective oil, which is another industrial pipe alternative, are cold rolled products. The protective oil layer creates an effective protection area on the industrial pipes and makes the product easier to use.

|

Industrial Pipes and Profiles

|

|

Production Standards

|

Steel Grades

|

Production Range

|

|

|

|

Pipe

|

Thickness (mm)

|

Profile

|

Thickness (mm)

|

|

EN 10305-3

|

E155- E700

|

08-0114,3

|

0,60 MM-2,00 MM

|

|

|

|

EN 10305-5

|

SURFACE CONDITION S1.S2.S3.S4

|

|

|

10×10-140×80

|

0,70-2,00

|

|

|

S1 (black)

|

|

|

|

S2 (pickled)

|

|

|

|

S3 (cold rolled)

|

|

|

|

S4 (coated on an agreed surface condition)

|

|

Steel Pipes – For Sensitive Applications – Cold Welded Pipes

Steel Profiles-Cold Dimensioned Welded Square and Rectangular Pipes for Sensitive Applications

Industrial pipes, which can also be produced in different qualities according to the needs, are mainly manufactured from DC01 – 6112 quality steel bands in the CR and DKP groups, and from S235JR and S275JR quality steel bands in the hot group.

Hot-rolled products with a wall thickness of 2.00 mm and above and diameters of 17 mm and above can be galvanized with the hot-dip galvanizing method.

Water-based painted in black, gray or brick red color for hot rolled products,

Cold rolled products can be produced with protective oil.