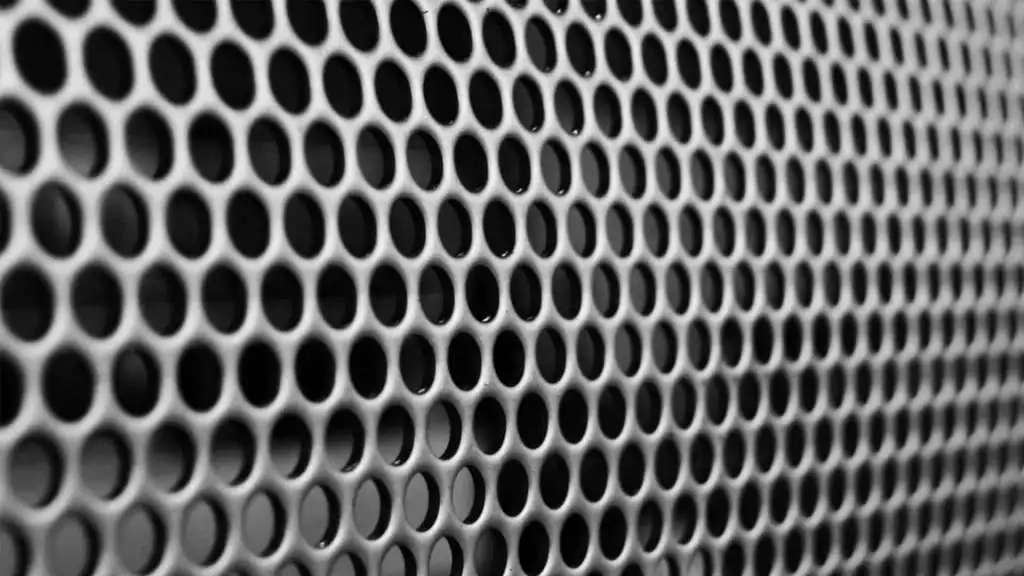

Perforated Sheet

What is Perforated Sheet?

Perforated sheet metal is metal sheet from which metal is removed from the hole. This type of metal generally consists of carbon steel, stainless steel or monel metal. It allows a variety of standard designs, thus making it useful for most purposes.

Most perforated sheet metal comes in sheets from 16 to 24 gauge, which is perfect for design. These types with round holes are best used for ventilation, decoration and protection. This design typically has a good strength-to-weight ratio. Also available in corrosion resistant varieties. According to experts, perforated sheet metal has a larger, more predictable and more accurate load bearing capacity than expanded metal or wire mesh.

This type of metal is generally used to create screens such as screen doors, windows or filters, as it is manipulated as simply as possible. Architectural accents are also usually made of perforated sheet metal, due to its flexibility and contributing to the character of a building or structure.

It is obtained by drilling flat sheets. Perforated perforated sheets are among the sheet types that are frequently preferred because they allow water and air to pass through easily. Due to this feature, it is actively used in different areas such as filtering as well as ventilation. Galvanized perforated sheet and metal perforated sheet, etc. Sheet types produced from different types attract attention with their thin and light structure.

Perforated sheet models have different types in the form of steel subjected to the cold rolling procedure and stainless steel. Metal perforated sheet models are produced with unique hole patterns. Perforated perforated sheets, which can be in different sizes, also attract attention with their maximum strength and high weight ratios. The products are very aesthetically attractive and versatile in their functional form. This type of sheet metal is very simple to both cut and manufacture.

Perforated perforated sheet materials, which offer a striking visual aesthetically, come to the fore with their high strength properties. The holes used in the sheet profiles increase the resistance as well as provide air and light permeability. In addition, the fact that it is known as the passage of gases and liquids brings along more use of perforated sheet metal materials in the industrial field.

Generally, home designers make changes in their home designs because they want to use perforated sheet metal. This type of architectural design is evident in new homes, with metalwork built into their design. In fact, it may be possible to purchase reasonable decorative plates for a wide variety of architectural design programs.

It is also possible to use it in the development of acoustic panels. Recording studios and office buildings near major transportation areas often have acoustic panels to mute or mute the sound. Perforated sheet metal is particularly reasonable for this use, due to the way the metal is made. The perforated fields actually “capture” sound waves.

Holes and lighting fixtures are generally made of perforated sheet metal, because the material is light and can be shaped simply. Many industrialized fixtures have been made for large warehouses, as well as enclosures for animals, and nearly every industry uses this device in some form. Often companies shape the metal according to the demand of a particular customer. Perforated sheet metal is very simple to use and manipulate.