Sandwich panel

Sandwich panel What is it?

Sandwich panel is the system that protects the structures from external factors and offers the easiest and most economical solution for a strong stance. sandwich panels; It is used as modern, light and durable building elements, to cover the roofs and facades of buildings, to obtain insulated interior partitions or cold stores.

Sandwich panels that protect you against external factors by taking place on all sides of your building and on the roof; It is produced by filling thick and low density insulation material between two thin high density metal surfaces. These structural elements, which have a high load carrying capacity despite their low weight, are produced in uninterrupted lines ready for assembly.

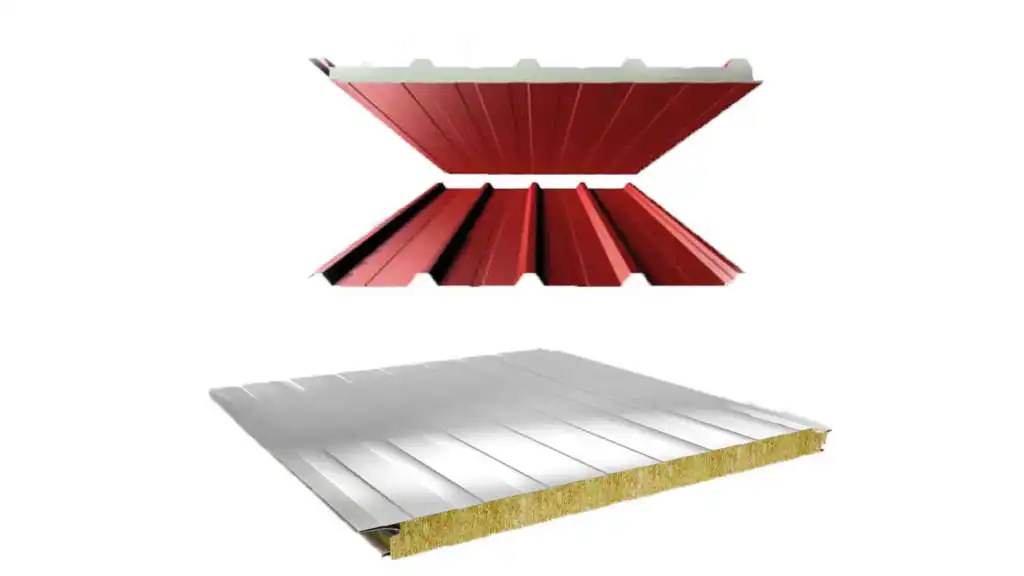

It is necessary to choose different insulation materials according to the needs of the buildings. Sandwich panels are produced in all insulation types, including PUR, PIR, Mineral Wool and EPS. Which Sandwich panel is reasonable for your building; You can choose by considering the heat, humidity, sound insulation and fire resistance needs of your building.

Sandwich panels are generally used in industrial facilities, commercial buildings, cold stores, social structures, power plants, agriculture and livestock structures.

Lifespan of the sandwich panel

Sandwich panel, which is a composite product, consists of two metal surfaces and insulation material coming together. The preservation of the long-lasting structure of the sandwich panels depends on the design of the product components by choosing the right technical specifications according to the needs of the building, the environment and climatic conditions.

The outer surface of the sandwich panels must be resistant to temperature changes, UV rays and external environmental conditions. The inner surface must be resistant to chemical and physical effects and condensation that may arise from the internal environment of the building.

In addition, the bearing capacities of Sandwich panels formed with the insulation material used in accordance with the needs of the building should be calculated correctly according to the loads they will be exposed to.

After the assembly made in accordance with the standards, sandwich panels and accessories should be checked at least once a year and cleaned and maintained. Damages caused by environmental conditions should be repaired without delay.

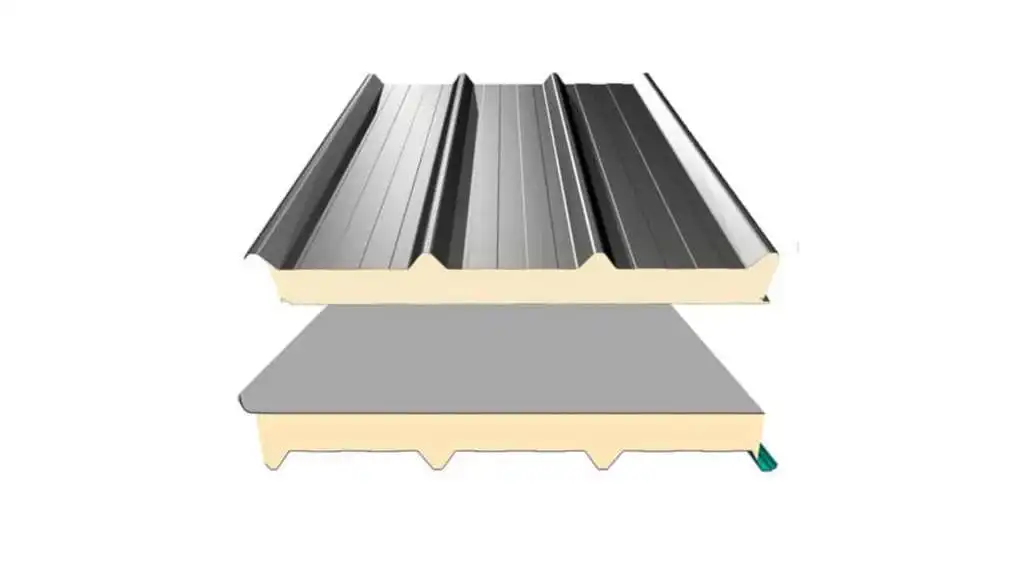

Sandwich panel Layers

Sandwich panels that provide fire and load resistance as well as heat, sound and water insulation for your buildings;

It is produced in 3 layers as inner surface, outer surface and insulation layer.

Sandwich panel Application Areas

Sandwich panel; It is a durable and economical solution for many structures from factories to stadiums, from shopping centers to swimming pools. In addition to industrial and social areas, the sandwich panel stands out as a more preferred product in the world with its new application areas such as military buildings, prefabricated buildings, construction site buildings, silos and residences.