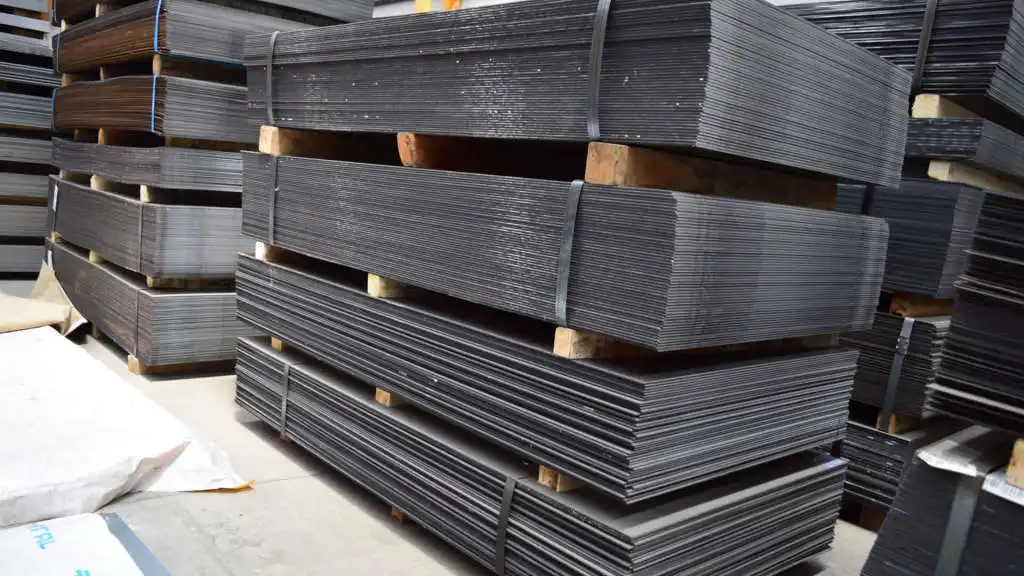

ST37 Black Sheet

It is a flat steel in the form of rolls or sheets, the thickness of which varies in the range of 1.50 – 20.00 mm, obtained by hot rolling of the semi-product of rectangular cross section, which is called slab and is formed as a result of solidification of the liquid steel with the continuous casting technique, in the hot rolling mill.

ST37 Black Sheet Black sheets are flat steels produced by hot rolling. They are the most produced and consumed products in Turkey and in the world. Especially in developed and developing countries, its production and consumption is increasing every year. The usage areas of black sheets are very wide.

ST37 Black Sheet Black sheets are produced between 1.50 mm – 20.00 mm. S235JR(ST37) quality is one of the most preferred grades in the world market and in our country.

The grades produced with S235JR, S275JR, S355JR notations within the scope of EN 10025-2:2004 standard are designed as Class 1 or Class 3 in accordance with the hot-dip galvanizing method, and other necessary information is given in the quality tables included in the hot products.

Product requests suitable for galvanized coating should be specified at the order stage.

Their quality

|

Hot Rolled Non-Alloy Structural Steels

|

|

Standard Equivalent

|

ERDEMİR Quality No

|

C d(thickness, mm)

|

Mn

max,

|

P

max,

|

S max,

|

Si

max,

|

Cu

max,

|

N(1) max,

|

CE(IIW) (4) max, (%) d (mm)

|

|

<16 max,

|

16<d<40

max,

|

40<d<100 max,

|

|

Standard

|

Quality

|

<30

|

30<d<40

|

40<d<100

|

|

EN 10025-2

|

S235JR+AR

|

3237

|

0,17

|

0,17

|

0,20

|

1,40

|

0,035

|

0,035

|

–

|

0,55

|

0,012

|

0,35

|

0,35

|

0,38

|

|

EN 10025-2

|

S235JR+AR

|

3137(14)

|

0,17

|

0,17

|

0,20

|

1,40

|

0,035

|

0,035

|

–

|

0,55

|

0,012

|

0,35

|

0,35

|

0,38

|

|

EN 10025-2

|

S235JR+AR CTB (Cu)

|

328168

|

0,17

|

0,17

|

0,20

|

1,40

|

0,035

|

0,035

|

0,14-0,25

|

0,55

|

0,012

|

0,35

|

0,35

|

0,38

|

|

EN 10025-2

|

S235JR+AR CTA

|

4237(7)

|

0,17

|

0,17

|

0,20

|

1,40

|

0,035

|

0,035

|

0,03

|

0,55

|

0,012

|

0,35

|

0,35

|

0,38

|

|

EN 10025-2

|

S235JR+AR Özel CTA

|

42387X11X15)

|

0,06-0,17

|

–

|

–

|

1,20

|

0,025

|

0,025

|

0,03

|

0,55

|

0,012

|

0,35

|

–

|

–

|

|

EN 10025-2

|

S235JR+AR Özel

|

426011X12X15)

|

0,050-0,095

|

–

|

–

|

0,30-0,45

|

0,015

|

0,025

|

0,05

|

0,55

|

0,012

|

0,35

|

–

|

–

|

|

EN 10025-2

|

S235JR+AR CTA

|

4437 ™15)

|

0,17

|

–

|

–

|

1,40

|

0,035

|

0,035

|

0,03

|

0,55

|

0,012

|

0,35

|

0,35

|

0,38

|

|

EN 10025-2

|

S235JR+AR CTA

|

5437(8)

|

0,17

|

0,17

|

0,20

|

1,40

|

0,035

|

0,035

|

0,14-0,25

|

0,55

|

0,012

|

0,35

|

0,35

|

0,38

|

|

EN 10025-2

|

S235JR+AR CTB

|

6237(2)(8)

|

0,17

|

0,17

|

0,17

|

1,40

|

0,025

|

0,025

|

0,14-0,25

|

0,55

|

–

|

0,35

|

0,35

|

0,38

|

|

EN 10025-2

|

S275JR+AR

|

324415)

|

0,20

|

0,21

|

0,22

|

1,50

|

0,035

|

0,035

|

–

|

0,55

|

0,012

|

0,40

|

0,40

|

0,42

|

Descriptions

- In the chemical composition of the steel, min. For grades with 0.020% Al, the upper limit value of N is not applied.

- In the chemical composition of the steel, min. For grades with 0.020% Al, the upper limit value of N is not applied.

4) The carbon equivalent is calculated according to the formula CEV (IIW) % = C + Mn / 6 + (Cr + Mo + V) / 5 + (Ni + Cu) / 15.

7) “It is suitable for galvanized coating as “Category A”. In category A, Si < 0.030% and Si+2.5P < The 0.090% limit applies.

8) “It is suitable for galvanized coating as “Category B”. In category B, Si 0.14< Si <0.25% limit applies.

9) Compliance classes for galvanized coating In Category A, Si < 0.030% and Si+2.5P < 0.090% limit. In category B, Si 0.14< Si <0.25% limit. In category D, Si 0.25< Si <0.35% is applied as the limit.

10) These grades are produced as “Special” within the framework of agreements made with the customer.

12) Nb %: Contains 0.015-0.050.

13) Ti can be added depending on the production results.

14) Erdemir 3137 quality is only for pipe production orders and Max. It is produced up to 8 mm.

15) Max. It is produced up to 8 mm thickness.

16)Max. It is produced up to a thickness of 16 mm.

|

Chemical Composition (%)

|

|

Standard Equivalent

|

ERDEMİR

|

C

|

Mn

|

P max.

|

S max.

|

Si max.

|

Cu max.

|

N4

|

CE(IIW)(6) max. (%)

|

|

Standart

|

Kalite

|

Kalite No

|

max.

|

max.

|

max.

|

|

EN 10025-2

|

S235JR+AR Özel

|

3235(2)

|

0,17

|

1,4

|

0.035

|

0.035

|

0,4

|

0,55

|

0.012

|

0,35

|

|

EN 10025-2

|

S235JR+AR CTA

|

4275811)

|

0,17

|

1,2

|

0.025

|

0.035

|

0,03

|

0,55

|

0.012

|

0,35

|

|

EN 10025-2

|

S235J2S235J2+N CTA

|

4239(5(8)

|

0,17

|

1,4

|

0.025

|

0.025

|

0,03

|

0,55

|

|

0,35

|

Descriptions

- The quality specified in this table is produced at İsdemir facilities within the framework of agreements made with customers.

- In this quality, it is produced in such a way that roll breakage does not occur.

- Mechanical testing is not performed according to production practices.

- In the chemical composition of the steel, min. For grades with 0.020% Al, the upper limit value of N is not applied.

- These grades are produced as fully stagnant and have a minimum Al/N ratio of 2:1.

- The carbon equivalent is calculated according to the formula CEV (IIW) % = C + Mn / 6 + (Cr + Mo + V) / 5 + (Ni + Cu) / 15.

- For S275 and S355 grades, max. carbon equivalent (CEV) is increased by 0.02% for %Si ≤ 0.04 and 0.01% for %Si ≤ 0.25.

- “It is suitable for galvanized coating as “Category A”. Si ≤ 0.030% and Si+2.5P ≤ 0.090% limits are applied in Category A class.

- “It is suitable for galvanized coating as “Category B”. Si 0.14≤ Si ≤0.25% limit is applied in Category B class.

- In line with production practices, the suitability for galvanized coating can be considered subject to negotiation at the order stage. Classes of suitability for galvanized coating Category A

Si ≤ 0.030% and Si+2.5P ≤ 0.090% limit in Class B, Si 0.14≤ Si ≤0.25% limit in Category B, Si 0.25< Si ≤0.35% is applied as the limit.

- Max. It is produced up to 8 mm thickness.

Usage areas

ST37 Black Sheet weldable general structural steels,

- In the manufacture of construction machinery and construction machinery,

- In general construction boards,

- In the manufacture of road and railway vehicles,

storage tanks,

- Container manufacturing,

- Pressure vessels or boiler manufacturing,

- In LPG production,

- It is used inside the ship and on the keel.