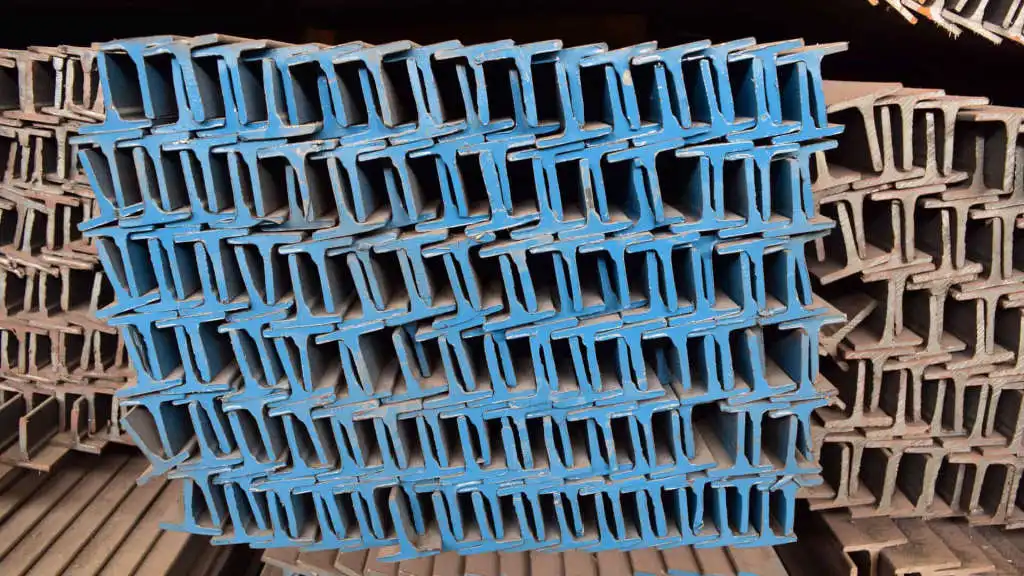

T Iron

T profile iron is a very diverse and useful product. It provides simplicity and convenience in different areas. T profile iron is generally preferred to provide connections between two different or two same floors. It is also called transition profile in some areas. The areas where the most basic benefit is provided are heavy transportation areas. While the upper parts of T profile irons are extremely strong against stresses and pressures; the vertical part has a strong feature against bending and cutting. They are common manufacturing products. It provides simplicity in many different areas of the automotive industry. The most primary crew of trailers are body elements. T profile irons, which are among the basic building materials, are known for being products that are used as structural carriers. T profile irons, which take their name from their shape, are also known as T beams. The product, which is the abandonment of building materials, is among the parts that are very important when looking at the superiority of use. T profile iron, which is offered with its durable feature, is used in most areas with its high strength.

- It is used very frequently in the construction industry.

- It is frequently used in entertainment and workplace areas, especially in airports, fairgrounds, shopping centers.

- Due to its structure, the construction industry provides convenience to its employees.

- It is one of the strongest team members to be able to handle heavy loads.

- It has the feature of not concentrating the weight in the structures an making the structure more robust.

- It is inverted T light shape.

Where are the Usage Areas

T Iron It is also called transition profile in some areas. The areas where the most basic benefit is provided are heavy transportation areas. While the upper parts of T profile irons are quite strong against stresses and pressures; the vertical part has a strong feature against bending and cutting. They are common manufacturing products. It provides convenience in many different areas of the automotive industry. The most primary crew of trailers are body elements.

T profile iron prices are expressed quite economically when looking at the advantages gained with the use of the product. The product, which is used as a carrier in buildings, is also used for fixing the weight sections of elevators, machines and many other parts. The main reason why it is effective in fixing weight is that the product offers high strength.

T profile iron, which offers its high strength feature, draws attention as the superiority it offers in more uses than its usage area. T anchors are used in fence manufacturing, barrier manufacturing, machinery industry, agriculture industry, furniture and automotive industry. You need to pay attention to some details in the purchase of T profile irons, which make room for use in shelves, in the preparation of display furniture and in warehouse areas.

Their quality

S235JR 5437 QUALITY MECHANICAL PROPERTIES

|

Mechanical Properties

|

|

|

Standard Equivalent

|

ERDEMİR

Quality No

|

Re (min) N/mm2 ( kg/mm2 ) d(thickness, mm)

|

Rm(1)

N/mm2 ( kg/mm2 ) d(thickness, mm)

|

A (%) min.

d(thickness, mm)

|

Darbe (3) (Longitudinally)

|

|

A80

|

A5

|

|

<16

|

>16

<40

|

>40

<63

|

>63

<80

|

>80

<100

|

<3

|

>3

<100

|

>1

<1.5

|

>1.5

<2

|

>2

<2.5

|

>2.5

<3

|

>3

<40

|

>40

<63

|

>63

<100

|

Sıc.

°C

|

KVc

J(min.)

|

|

Standard

|

Quality’81

|

|

EN 10025-2

|

S235JR+AR CTB

|

5437

|

235 (24.0)

|

225 (23.0)

|

215

(21.9)

|

215 (21.9)

|

215

(21.9)

|

360-510 (36.7-52.0)

|

360-510 (36.7-52.0)

|

16

|

17

|

18

|

19

|

24

|

23

|

22

|

+20

|

272)

|

CHEMICAL COMPOSITION OF S275JR 3244

Standard: EN 10025-2:2019

|

Chemical Composition (%)

|

|

Standard Equivalent

|

ERDEMİR

|

C d(thickness, mm)

|

Mn

|

P

|

S

|

Si

|

Cu

|

N(1)

|

|

CE(IIW) (4) max. (%)

|

|

|

|

Quality No

|

<16

|

16<d<40

|

40<d<100

|

|

|

|

|

|

|

|

d (mm)

|

|

|

Standard

|

Quality

|

|

max.

|

max.

|

max.

|

max.

|

max.

|

max.

|

max.

|

max.

|

max.

|

<30

|

30<d<40

|

40<d<100

|

|

EN 10025-2

|

S275JR+AR

|

3244(1)

|

0.21

|

0.21

|

0.22

|

1.50

|

0.035

|

0.035

|

–

|

0.55

|

0.012

|

0.40

|

0.40

|

0.42

|

For S275 and S355 grades, max. Carbon equivalent (CEV) can be increased by 0.02% for %Si ≤ 0.04 and 0.01% for %Si ≤ 0.25.

S355JR 3252 CHEMICAL COMPOSITION Standard: EN 10025-2:2019

Chemical Composition (%)

|

Standard Equivalent

|

ERDEMİR

|

C d(thickness, mm)

|

Mn

|

P

|

S

|

Si

|

Cu

|

N(1)

|

|

CE(IIW) (4) max. (%)

|

|

|

|

Quality No

|

<16

|

16<d<40

|

40<d<100

|

|

|

|

|

|

|

|

d (mm)

|

|

|

Standard

|

Quality

|

|

max.

|

max.

|

max.

|

max.

|

max.

|

max.

|

max.

|

max.

|

max.

|

<30

|

30<d<40

|

40<d<100

|

|

EN 10025-2

|

S355JR+AR

|

3252(1)

|

0.24

|

0.24

|

0.24

|

1.60

|

0.035

|

0.035

|

0.55

|

0.55

|

0.012

|

0.45

|

0.47

|

0.47

|

For S275 and S355 grades, max. Carbon equivalent (CEV) can be increased by 0.02% for %Si ≤ 0.04 and 0.01% for %Si ≤ 0.25.