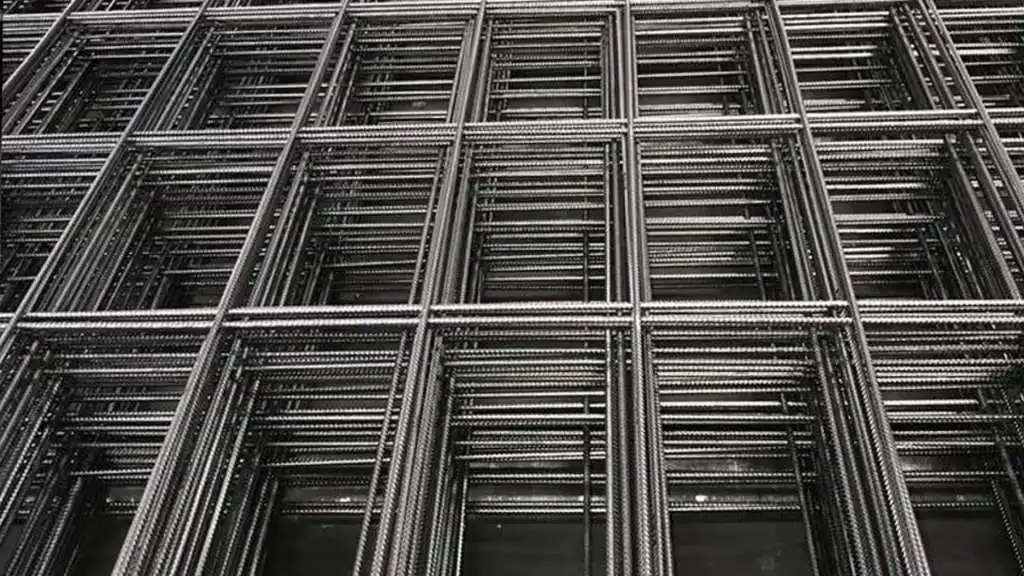

Wire Mesh

Wire mesh is a concrete steel that is produced from S220 steel by cold drawing technique and ribbed, has high strength and is generally used in constructions. Wire mesh rods, Bst IVb or Bst 50/55 (RK) according to international criteria, are obtained by drawing the low carbon normal St I iron by cold rolling procedure (by cold rolling) and then specially ribbed. The production of steel mesh is done by weaving the rods, which are wound on the drums during drawing, in automatic straightening and cutting machines, and then cut to the desired lengths in electronically applied spot welding machines. Wire mesh production is carried out in accordance with TS 4559, DIN 488, BS 4483, ASTM-A 497 criteria. Details about the concrete steel bars (S 500) used in wire mesh and stirrups are specified in TS 708. In addition, St IV b rods are used as ready stirrups in constructions. Where it is used, steel mesh is used as a building material, especially in floors, curtains, retaining walls, foundations, field concretes, concrete roads, tunnels and galleries, canals and flumes.

Advantages

1-) Material Saving: The safety stress of steel mesh is approximately twice that of normal rebar, and in case of using steel mesh, it provides weight savings of around 40% compared to normal rebar (STI). From STI iron, while for concrete 160 and = 1400 kg / cm2, for steel mesh this amount is and = 2400 kg / cm2, so the iron cross-section is reduced by half,

2-) Saving Time: The decrease in the material used in the steel mesh, the fact that it is in the form of plates, its simple transportation and simplicity of assembly greatly simplifies the time.

3-) Saving on Labor: There are no tasks such as straightening, cutting the rods wire by wire, breaking the pile, making hooks, placing them on the floor at certain intervals and connecting them together as in normal iron. Laying the steel mesh in a short time provides 50% savings.

4-) Saving on Transportation: Steel mats are manufactured in standard (500 x 2.15) type size, so transportation is simple. As it saves iron, shipping costs are reduced.

5-) Saving Money: Reduction of material by nearly half, shortening of time, saving from labor; As a result, all these provide financial savings of 10-20%.

6-) Superiority in Quality: Steel mats are manufactured with the desired precision in automatic welding marinas. The steel mesh rods show a homogeneous distribution in the concrete, thus ensuring that the tensile forces are taken properly. The ribbed and welded bars increase the tolerance.

Usage areas

If desired, it can also be supplied as hot-dip galvanized and polyester painted.

- On the decks of reinforced concrete structures; beamless floors, curtains,

- ribbed floors, regular B.A. plaques, foundations

- In individual and radial foundations,

- On curtain and retaining walls,

- In concrete runways, highways and field concretes

- Metro and tunnel construction, (used in Istanbul Metro).

- In water structures; in dams, canals and canals,

- In prefabricated building elements,

- It is used in various constructions of industrial buildings, suspended

- ceilings, fences, etc. possible to use anywhere.

- Channel, flumes, garden fence, balustrade, suspended ceilings

Types

Standard steel mesh is produced in two types as R and Q.

R TYPE MESH: It is used for floors and support equipment running in one direction. In all R type meshes, the length bar spacing is 150 mm, the width bar spacing is 250mm.

Q TYPE MESH: It is used on floors running in both directions and reinforced concrete building elements.

Length and width bar Intervals are 150 mm.

Standard mats are 5.0/2.15 m. It is simple to carry. Length bars can be even, while the width bar is always odd. Special production is also made. Maximum length bar is 8 m, maximum width is 2.80 m. cm2/m in each section. Special wicker is produced.

Their quality

S220GD+Z 1322 CHEMICAL COMPOSITIONS

Galvanized Structural Steels with Zinc Coating Standard: EN 10346 : 2015

|

Chemical Composition (%)

|

|

|

Standard Equivalent

|

ERDEMİR

Quality No

|

C max.

|

Si

max.

|

Mn

max.

|

P max.

|

S max.

|

|

Standard

|

Quality

|

|

EN 10346

|

S220GD+Z

|

1322

|

0.20

|

0.60

|

1.70

|

0.10

|

0.045

|

|

EN 10346

|

S250GD+Z

|

1325

|

0.20

|

0.60

|

1.70

|

0.10

|

0.045

|

|

EN 10346

|

S280GD+Z

|

1328

|

0.20

|

0.60

|

1.70

|

0.10

|

0.045

|

|

EN 10346

|

S320GD+Z

|

1332

|

0.20

|

0.60

|

1.70

|

0.10

|

0.045

|

|

EN 10346

|

S350GD+Z

|

1335

|

0.20

|

0.60

|

1.70

|

0.10

|

0.045

|

S220GD+Z 1322 MECHANICAL PROPERTIES

|

Mechanical Properties’4)

|

|

|

Standard Equivalent

|

ERDEMİR

Quality No

|

Rp0.2/ReH N/mm2 (kg/mm2) min.

|

Rm(1)(3) N/mm2 (kg/mm2) min.

|

A80(2) (%) min.

|

|

Standard

|

Quality

|

|

EN 10346

|

S220GD+Z

|

1322

|

220

(22.4)

|

300 (30.6)

|

20

|

|

EN 10346

|

S250GD+Z

|

1325

|

250

(25.5)

|

330 (33.6)

|

19

|

|

EN 10346

|

S280GD+Z

|

1328

|

280

(28.6)

|

360 (36.7)

|

18

|

|

EN 10346

|

S320GD+Z

|

1332

|

320

(32.6)

|

390 (39.8)

|

17

|

|

EN 10346

|

S350GD+Z

|

1335

|

350

(35.7)

|

420 (42.8)

|

16

|

Descriptions

- Tensile test values are applied to ‘longitudinal’ test specimens.

- “Min. The value of “% elongation” is decreased by 4 units for the thickness range 0.35 mm < t < 0.50 mm, and by 2 units for the 0.50 mm < t < 0.70 mm range.

- The tensile strength range is expected to be 140 N/mm2 (14.3 kg/mm2).

- The mechanical properties specified in the table are guaranteed for 1 month, starting from the date the material is reported to be manufactured and ready for shipment.