Fire Safety Installation Pipes

Underwriters Laboratories (UL)

It is an international independent engineering and security company operating in 5 main strategic branches (Product Safety, Environment, Health, University and Verification Services).

Factory Mutual (FM)

It is one of the largest insurance companies in the world, providing engineering solutions to protect against risks such as fire, natural disasters and so on. FM Approvals; FM Approvals is the unit of FM Global that certifies industrial commercial products and services for companies.

Bending Moment Strength

Bending moment tests are applied to the system formed with the fittings mounted at the ends of the samples. Pipe ends are specially prepared for the fittings by the manufacturer. By applying the pressure values determined for the test to the fittings at the specially prepared ends; bending moment under pressure is examined. This test is done to test the strength of pipes and fittings under a certain load. Connection strength of pipes under pressure is tested.

Rotation Bending Moment Resistance

Fitting groups of each nominal pipe size considered for approval are tested and conformity is verified by this test method. It is verified that there is no leakage, cracking, breakage or pipe deformation before, during and after the bending bending moment applied under the nominal working pressure in the assembly prepared by assembling with approved fittings, and that it remains sealed while pressurized to the nominal working pressure.

Hydrostatic Strength

This test is performed using multiple connections along the same pipe or for separate assemblies for each joining method. Piping assemblies are hydrostatically tested at four times the rated working pressure. Each hydrostatic pressure test is performed for a period of five seconds.

Vibration Resistance

Compliance with vibration resistance testing is verified by testing at least one specimen assembly of each type. The prepared test apparatus is under hydrostatic nominal working pressure; It is exposed to vibration for 5 periods gradually increasing every 5 hours with specified vibration pulse increments. No leaks or other malfunctions are allowed during this 25 hour test. Next, the hydrostatic strength test is repeated after the vibration test of each batch of samples. Verify that there are no leaks or other malfunctions.

Marking Durability

Pipe markings must remain legible under conditions of storage, transport and use to ensure product identification. The durability and suitability of the marking is therefore verified by immersing the clear marked area on the approximately 450 mm long portion of the pipe in water for five minutes once a day for 10 working days. In these routinely repeated daily operations; After the samples are removed from the water, the marking area is dried by wiping it vigorously with a cotton or paper towel. If the marking does not smudge, spill or leave residue on the towels, after completion of the 10-day water exposure test, the markings on the sample are coated with petroleum-based grease and should be kept intact for 24 hours. After this time, the oil is cleaned from the sample surface by wiping with cotton or paper towel. Verify that the pipe marks are not erased, smeared or otherwise removed.

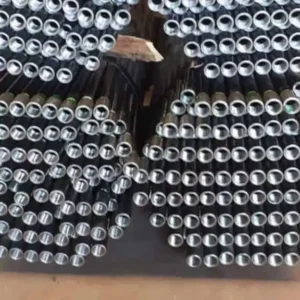

Corrosion Resistant Coatings

For hot-dip galvanized coatings, pipe samples for all coated sizes are examined and their suitability is verified. Samples are cut from a full-length pipe after coating. A total of three samples are taken from the two free ends and the center of the full-length pipe, with the length of the samples approximately 600 mm. Measurements are made at a distance of approximately 100 mm from the tip, evenly spaced around the outer diameter. NPS 2 (DN50 – 60.3mm) pipes require a minimum of four measurements around the outside diameter, and smaller, larger NPS 2 (DN50 – 60.3mm) pipes require a minimum of six measurements. The sample tube should show an average coating thickness of 77 microns (55 g / m2) on each sample, regardless of the standard from which it is made. The coating thickness should not be less than 64 microns (0.46 kg / m2) at each measured point.