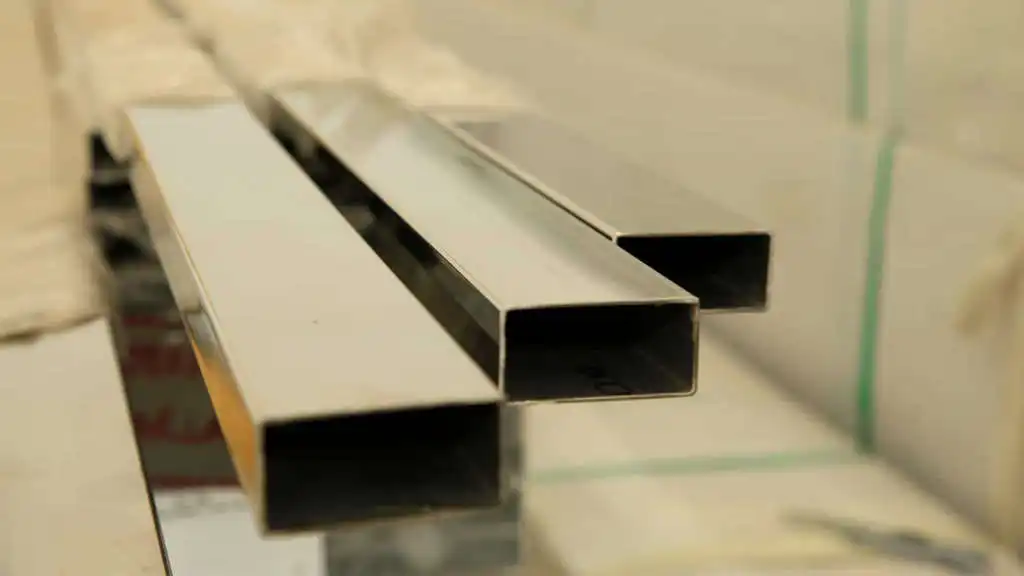

Stainless Profile

Steels with stainless properties are called Stainless profiles. Stainless profiles obtained with steel and chrome alloys allow the steel to be used by shaping. The shaped form of steel provides great simplicity as it can be used directly in most industries.

One of the sectors where stainless profiles are used the most is the decoration sector. Especially with the addition of nickel into the Stainless profile alloys, the Stainless profiles have been made more decorative. Thus, Stainless profiles have become more frequently used in many sectors, especially in decoration.

Since stainless profiles have extremely high corrosion, heat and oxide resistance, they are used in many areas from construction to heavy industry, from heavy industry to shipbuilding.

Usage areas

Stainless profiles are used in many areas from decoration to architecture, from architecture to heavy industry, together with the advantages they provide. The usage area may also change according to the advantages provided by the Stainless profiles, each type of which can be used in different sectors.

The areas where stainless profiles are used frequently are as follows.

- At most points of the architectural fields and the construction industry,

- In the creation of vehicles in the automotive and sub-industry sector,

- At most points of the decoration industry,

- In the furniture industry, especially in the legs and arms of armchairs, chairs and tables,

- Clothes hangers and mannequins, which are reasonable to look more decorative in the textile sector,In shipbuilding and the same in heavy industries,

- It is used in the production stages of electronic devices in the technology sector.

Their quality

304 (1.4301) Quality Stainless Steel

|

Corrosion Resistance:

|

This quality, which is quite sufficient for daily use and standard productions, is not preferred because it will rust in more corrosive environments. In more demanding conditions, 316, 316L, 316Ti or duplex (1.4462) grade stainless steel should be preferred instead of 304 grade stainless steel.

|

|

Mechanical Properties:

|

This stainless steel quality, which is often sufficient in terms of mechanical strength, is not preferred where high yield and rupture strength is required. When the mechanical properties come to the fore, considering the material structure,

|

|

Tendency to Forge:

|

This quality material has a standard malleability. It should not be preferred in places where metal forging is extremely intense.

|

|

Weldability:

|

Plain 304 quality stainless steel is an ideal material for places where there is no excessive welding. In places where the weld is more intense, 304L quality material with lower carbon (L=low carbon) should be preferred to prevent swelling.

|

|

Machinability:

|

This material, which is not bad in terms of machinability, is not preferred in places where processing is intense. 304 quality stainless steel is less preferred, especially in lathes and machining centers, as it wraps chips. In places where this type of process is intense, 303 quality stainless steel, which is the automatic version of 304, should be preferred.304 (1.4301) Kimyasal Bileşimi

|

|

Chemical Composition

|

|

Quality

|

C

|

Mn

|

P

|

S

|

Si

|

Cr

|

Ni

|

|

304 (1.4301)

|

%0.08 max

|

%2,0 max

|

%0.045 max

|

%0.03 max

|

%0,75 max

|

%18-20

|

%8-10

|

|

Mechanical Properties at Room Temperature

|

|

Quality

|

304 (1.4301) X5CrNi18-10

|

|

breaking strength

|

515 – 720 MPa

|

|

Yield strength (0.2%)

|

210 MPa (min)

|

|

Hardness, Rockwell (HB)

|

201

|

|

|

|

|

|

Physical Properties at Room Temperature

|

|

Features

|

Values

|

|

Density (Specific gravity)

|

8000 kg/m³

|

|

Melting temperature

|

1450°C

|

|

Modulus of Elasticity

|

193 GPa

|

|

amount of electrical resistance

|

0.072×10^-6 Ωm

|

|

heat permeability

|

17.2 W/m.K

|

|

|

|

|

|

Summary of Quality Characteristics

|

|

304 stainless is numbered as 1.4301 quality stainless according to the EN standard.

|

|

304 quality stainless is also called X5CrNi18-10 according to EN standard.

|

|

This stainless quality is in the category of esthenitic stainless steels.

|

|

Materials of this stainless steel grade can be well formed and welded well.

|

|

Stainless steels of this quality do not attract magnets and have a high corrosion resistance.

|

|

General features

|

Explanation

|

|

Corrosion Resistance:

|

The corrosion resistance of this material is quite good. Duplex (1.4462) quality material can be preferred in harsher environments.

|

|

Mechanical Properties:

|

316L quality material shows similar mechanical properties to 304 and 304L quality materials. For higher mechanical strength, 431, duplex (1.4462) or 630 (1.4542 PH17.4) can be preferred.

|

|

Tendency to Forge:

|

This grade of stainless steel has a good malleability tendency. Due to the low carbon content, the risk of breaking and cracking during forging is lower.

|

|

Weldability:

|

Weldability of this quality stainless is good. Due to its low carbon content, carburization is minimized during welding.

|

|

Machinability:

|

All 316L quality western materials sold by our company have good machinability. 303 or 430F quality stainless steel products can be preferred for easier machinability in environments where corrosion resistance is unimportant.

|

|

Chemical Composition

|

|

Quality

|

C

|

Mn

|

P

|

S

|

Si

|

Cr

|

Ni

|

Mo

|

|

316L (1.4404)

|

0.030

|

|

|

|

|

|

10,0-

|

|

|

2

|

0.045

|

0,03

|

1

|

16.0-18.0 between

|

14 between

|

2.0-3.0 arası

|

|

Mechanical Properties at Room Temperature

|

|

Quality

|

316L (1.4404)

|

|

X2CrNiMo17-12-2

|

|

Breaking strength

|

Min 485 MPa

|

|

Yield strength, (0.2%)

|

Min 170 MPa

|

|

Hardness, Rockwell (HRC)

|

max 22 HRC

|

|

Summary of Quality Characteristics

|

|

316L stainless is numbered as 1.4404 quality stainless according to EN standard.

|

|

316L quality stainless is also called X2CrNiMo17-12-2 according to EN standard.

|

|

316 and 316L quality stainless is one of the most widely used stainless steel grades in the world, along with 304 quality stainless.

|

|

This stainless quality is in the category of esthenitic stainless steels.

|

|

Materials of this stainless steel grade can be well formed and welded well.

|

|

Stainless steels of this quality do not attract magnets and have a high corrosion resistance.

|

|

The corrosion resistance of 316L grade stainless steel is better than 304 and 304L grade stainless steel.

|